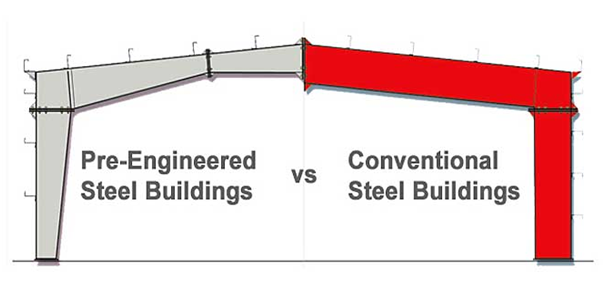

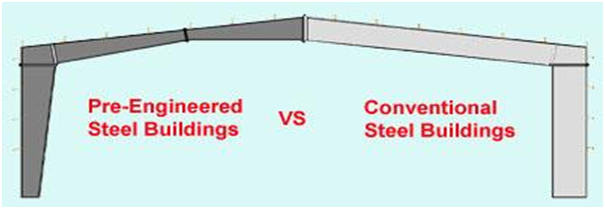

In conventional steel Buildings, mill produce hot rolled sections (Beams & Columns) are used. The size of each member is selected on the basis of the maximum internal stress in the member. The hot rolled sections have a constant depth, many part of the member, in areas of low internal stresses, and are in excess of design requirements

Frames of Pre-Engineered Buildings are made from extensive inventory of standard steel plates stocked to the Pre-engineered Building. Pre-Engineered Building Frames are normally tapered and often have flanges & web of Variable thickness along the individual Members.

The Frame geometry matches the shape of internal stress (Bending Moment) diagram thus optimizing material usage and reducing the total weight of structure, also the entire rigid frame is allow to sway in tolerable limit hence low reaction & moment on RCC footing save the cost of RCC footing & pedestals.